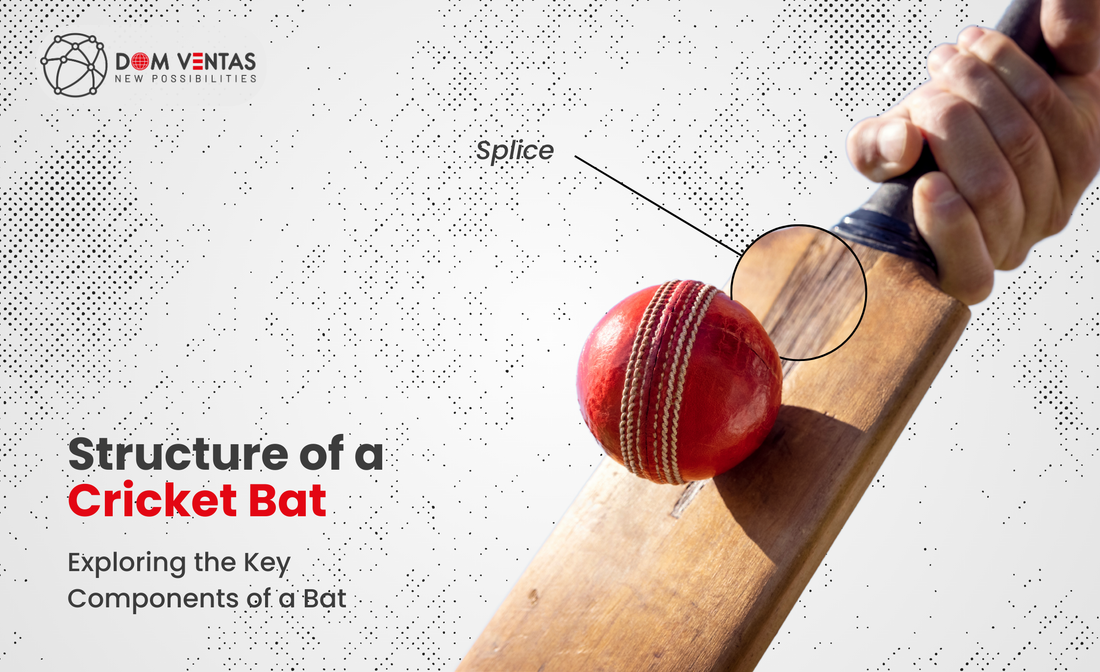

Structure Of Cricket Bat: Exploring the Key Components of a Cricket Bat

Cricket bats have evolved a lot since the early days of the game. While shaped bats are a part of cricket history, this article focuses on the latest designs used in international matches. Before we look at the key components of modern bats, let's briefly revisit a unique shaped bat - the Mongoose bat.

The Mongoose bat, occasionally used by players such as Matthew Hayden (IPL 2010), Suresh Raina (vs Delhi Darevils 2010) and Kapil Dev (1983 World Cup), is a notable but short-lived innovation. This bat featured a long handle and a short, thick base that enabled batsmen to hit powerful, high shots. The shorter blade also created a pronounced sweet spot that was ideal for hitting sixes.

Although the Mongoose bat was effective for power hitting in limited overs cricket, it fell out of favour due to its limited shot variety and defensive play. Today it is no longer used, but its popularity and controversy make it worthy of a mention.

Unlike the Mongoose bat, modern cricket bats are designed to provide a balance of power, control and versatility. Choosing the right bat depends on various factors, which I have discussed in more detail in another article: How do international cricketers choose their cricket bat? First, let's examine the main components of a cricket bat: the handle, the splice and the blade.

The handle

The handle is where the player holds the cricket bat and provides control and stability. It is mainly made of Singapore cane, known for its stiffness and strength, combined with rubber inserts for shock absorption.

There are different types of grips available to suit different playing styles:

12-piece handle

6-piece handle

4-part handle

Round handle

semi-oval handle

Oval handle

The combination of reed and rubber provides durability and comfort, which is crucial for handling high-impact deliveries.

The splice

The splice is the triangular area where the handle and blade are joined. A V-shaped notch is carved into the blade of the club into which the handle fits securely. This joint increases the strength and durability of the club and ensures that it can withstand the rigors of play.

The Blade

The blade is the hitting surface of the club, which is usually flat on the front and ridged on the back. The ridge bundles the wood in the middle, creating a powerful "sweet spot" for the ball.

Traditionally, cricket bats were made from one piece to ensure uniformity and strength, but as technology has advanced, double-edged bats have been introduced, where two pieces are joined together. These bats have become increasingly popular for training purposes, although one-piece bats remain the professional standard due to their superior durability and performance consistency.

Cricket bat blades are made from willow wood, which is valued for its strength and lightness. Two types of willow wood dominate the market:

English Willow: A soft, fibrous wood preferred for professional bats due to its exceptional performance and shock absorption.

Kashmir Willow: A denser, harder wood often used for entry-level and recreational clubs. It is affordable and durable, but lacks the performance characteristics of English Willow.

The type of willow affects the weight, balance and alignment of the bat for different playing styles and is therefore a crucial factor when choosing a cricket bat.

From the experimental Mongoose bat to the modern willow-crafted designs, cricket bats have evolved to meet the different needs of players. Whether it's the handle, splice or blade, each component plays an important role in performance and reflects the mix of tradition and innovation in the sport.